Noise

Technical report relating to noise issues at Osier Lake Peterborough.

Introduction

This report has been compiled in order to proactively respond to the current noise problems we now all face when running R/C Multi boats

This report highlights the work which has been carried out by Peterborough Model Powerboat Club (PMPBC). This can also assist other clubs who run multi boats of all classes to combat any noise problems they may have.

1. Historic usage of Osier Lake, Peterborough

2. Testing methodology

3. Remedial works carried out

4. Post remedial work readings

5. General comments

6. Conclusions

7. Photographs

Historic usage of Osier Lake, Peterborough

PMPBC have historically operated radio-controlled multi boats both in Nene Park and subsequently at Osier Lake since August 1980

These readings were taken several years ago and at that time there was not deemed to be a problem, Since then, modern boats are now much faster, with high output glow and now petrol engines being used, and the general use of Carbon Fibre in the manufacture of the boat hulls. All of these factors contribute to the higher noise now being generated by multi boats.

To this end PMPBC took it upon themselves to carry out noise tests to determine the current noise levels

Testing methodology.

A calibrated tripod mounted noise test meter was installed at 1250mm above the water level and at a distance of 10 Metres from the path the test boats will take in accordance with MPBA recommendations, Multiple noise readings were taken using the Slow setting, db(A) and with the test boats at 90 deg to the noise meter.

The initial test results were disappointing and are as follows:

3.5cc- Typically in the region of 84-884B(A)

7.5cc- Typically in the region of 83-894B(A)

Some boats were slightly quieter, and some were noisier with the above readings being typical. It was also found that the loudest tuned pipes were the CMB and Nova Rossi pipes manufactured from Aluminium with PMB steel pipe being the quietest

Remedial works carried out

3.5cc

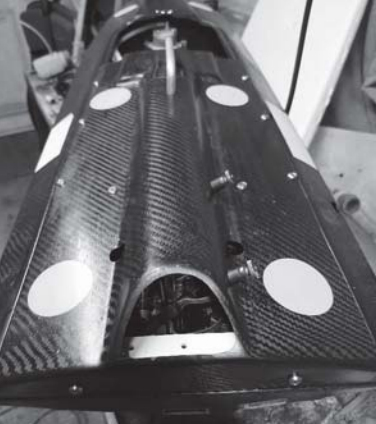

Numerous Carbon fibre bracing ribs installed between the hull and the top deck. See photo 1

Numerous Carbon Fibre bracing ribs installed to the underside of the tank cover, See photo 2

Additional mounting screws installed to secure the tank cover. See photo 3

Softer 45 Shore rubber bobbins installed onto the gearbox

Lengths of thick wall rubber tube installed into the gap between the tops of the tank/s and the top deck will reduce the vibration and hence noise.

PMB steel pipe installed

7.5cc

Numerous Carbon fibre bracing ribs installed between the hull and the top deck.

Additional mounting screws installed to secure the tank cover,

Softer 45 Shore rubber bobbins installed onto the gearbox,

Hull fully foamed using 2 pack expanding marine quality foam.

PMB steel pipe installed

15cc

Numerous Carbon fibre bracing ribs installed between the hull,

and the top deck. Additional mounting screws installed to secure the tank cover.

Softer 45 Shore rubber bobbins installed onto the gearbox,

Hull fully foamed using 2 pack expanding marine quality

PMB steel pipe installed

Post remedial work noise readings

3.5cc – Typically in the region of 78-824B(A)

7.5cc ~ Typically in the region of 80-8 14B(A)

General comments

As can be seen from the above readings the noise levels can be reduced down to an acceptable level with some fairly minor modifications being made to the boats.

General

Hard Male / Female rubbers and Female / Female gearbox rubber bobbins were found to transmit a lot of vibration and hence noise into the hull,

Soft (Shore 45) Male / Male gearbox rubber bobbins transmitted considerably less vibration and hence noise into the hull

PMB steel pipe found to be quieter than CMB and Nova Rossi by 1-dB(A).

The 3.5cc boats were of different design and construction, ranging from gel-coat Carbon Fibre to full Carbon Fibre,

There was no noticeable difference in the noise readings between coupling and solid shaft boats

There was a 2-44B(A) increase in the noise level when running, without an engine cover

Conclusions

installing multiple Carbon fibre bracing ribs between the bottom of the hull and the top deck will reduce the vibration and hence noise from the tank cover.

1. CF bracing on the tank cover

2. Install soft (Shore 45) rubber bobbins which will transmit less vibration and hence noise into the boat. Install additional securing screws to the tank cover to reduce vibration.

3. Fit an engine cover.

4. Fit a PMB steel pipe

Installing lengths of thick wall rubber tube into the gap between the tops of the tank’s and the top deck will reduce the vibration and hence nose into the top of the hull and tank cover.

To get the ultimate in noise reduction, fully foam the inside of the boat

Dear Sir, I was shown your article in Propwash about noise in model racing boats by a friend who races FSR in the UK. I am currently building an FSR 7.5 that I purchased from my friend who is guiding me through the building phase. It will take me most of this year to build as I’m currently serving in the RN. You raised some interesting points that I would like to comment about.

You mentioned Osier Lake readings taken a few years ago. You don’t say anything about those readings.

Did you take ambient noise level readings before you started your testing? Very important to give you a base line on ambient noise.

The remedial work work carried out using carbon fibre for bracing, are you assuming all boats are carbon fibre in there construction. You state PMB pipes are the quietest, was the testing done with CMB/Nova Rossi after installing ribs and securing the tank cover with more screws.

Why use 45 Shore rubbers? are they technically proven to be quieter as a mount, you don’t say. You suggest fully foaming the hull of the 7.5 boat but not the 3.5, is there a reason for this?

Not all tuned pipes suit the same engine, so why do you recommend PMB pipes over others.

An interesting thread that lacks a lot of information. Well done for taking this task on.

Dave S Jones

NW Yorkshire.